(1) Ultrasonic Cleaning MachineWorking principle: Utilize the "cavitation effect" generated by ultrasonic waves in the cleaning solution to form the impact force when tiny bubbles burst, peeling off stubborn stains (such as polishing wax, sintered carbides) on the surface of parts.Advantag...

1. Pretreatment before processingRemove blank impurities: Sand, scale, release agents, etc. on the surface of casting and forging blanks need to be removed before machining to avoid contaminating the cutting fluid and accelerating tool wear.Eliminate storage pollutants: Rust-proof oil, dust, etc. on...

more

The modular - designed cleaning machine can be adapted to different instruments, such as the stage of an electron microscope, the lens of a spectrometer, etc. The customized model introduced by a certain laboratory supports flexible cleaning intensity to avoid scratching precision optical components...

Industrial ultrasonic cleaning machines can thoroughly remove blood, tissue fluid, and biofilms from surgical instruments, especially those with complex structures (such as endoscopes and joint instruments). For example, ultrasonic technology can penetrate lumens and crevices through the cavitation ...

more

Wafer CleaningIn the front - end semiconductor process, metal ions, polishing particles (such as cerium oxide), and organic substances remaining on the wafer surface need to be thoroughly removed. Ultrasonic waves strip off contaminants through the high - frequency cavitation effect (20kHz - 1MHz). ...

As a precision optical component, the surface of a mobile phone lens can be significantly affected in imaging quality by nanoscale stains such as fingerprints, oil films, and dust. Ultrasonic cleaning technology, with its non - contact physical cleaning advantages, has become one of the core process...

more

During the semiconductor manufacturing process, minute contaminants on the surface and inside the chambers of equipment (such as particles, metal ions, organic substances, photoresist residues, etc.) may lead to:Decrease in chip yield: Contaminants adhere to the surface of the wafer, causing short c...

In the chip manufacturing process, the cleaning process before packaging is of great importance. During the previous manufacturing process of the chip, impurities such as photoresist, metal ions, particulate contaminants, and organic substances will remain on the surface. If these contaminants are n...

more

As the core equipment in semiconductor manufacturing, the components of a lithography machine have nanometer - level precision. Any slight contamination can lead to lithography pattern distortion, exposure energy deviation, and even equipment failure. Therefore, component cleaning is a crucial step ...

more

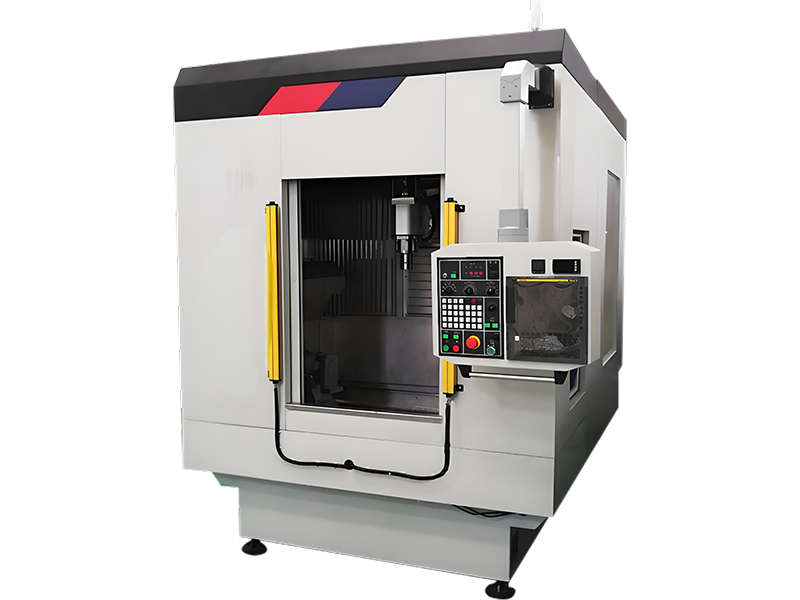

I. Core Cleaning ObjectsPower System Components: Key metal components such as engine blocks, cylinder heads, and crankshafts need to have machining -Residual cutting fluid, rust-proof oil and metal debrisremoved. Residual cutting fluid, rust - preventive oil, and metal debris from machining need to ...

more